⚗️ 1. Sodium Nitrate (NaNO₃)

🔄 Traditional Production Process:

Neutralization of nitric acid with sodium carbonate or sodium hydroxide.

⚙️ New/Improved Technologies:

Electrochemical nitration: Using green electricity to produce nitric acid more sustainably, reducing dependency on ammonia oxidation.

Closed-loop water systems: For nitrate salt crystallization, saving water and reducing waste.

🧠 Tech Shift Highlights:

Use of AI/ML to optimize crystallization and drying phases.

Adoption of solar thermal integration for energy-intensive drying in arid regions.

👥 Users/Applications:

Fertilizer manufacturing

Explosives (mining, defense)

Thermal energy storage (in molten salt systems for solar power plants)

Glass and ceramics industries

⚗️ 2. Sodium Acetate (CH₃COONa)

🔄 Traditional Production Process:

Neutralization of acetic acid with sodium carbonate or sodium hydroxide.

⚙️ New/Improved Technologies:

Bio-based acetic acid production: Fermentation of biomass to replace petrochemical acetic acid.

Continuous flow reactors: For more precise control of pH and purity.

🧠 Tech Shift Highlights:

Process integration with biorefineries to utilize acetic acid from lignocellulosic biomass.

Automation and real-time purity control using inline sensors.

👥 Users/Applications:

Textile industry (as a buffering agent in dyeing)

Food industry (as a preservative E262)

Pharmaceutical intermediates

Heating pads and phase-change materials

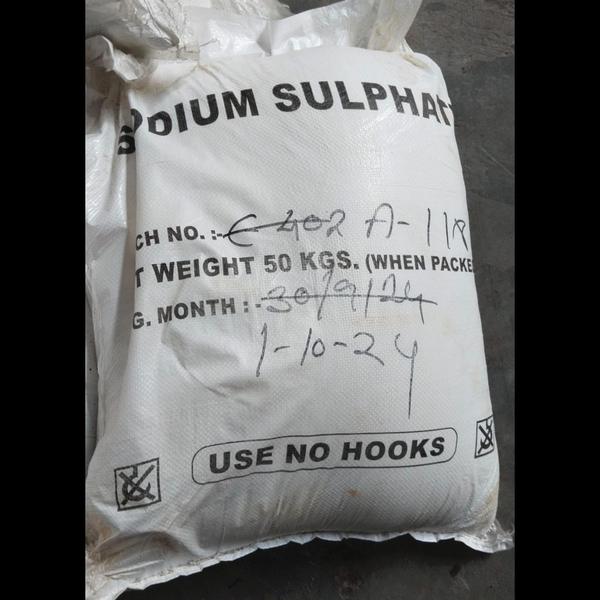

⚗️ 3. Sodium Sulfate (Na₂SO₄)

🔄 Traditional Production Process:

Natural mineral (mirabilite) processing or as a byproduct of HCl production with sodium chloride and sulfuric acid.

⚙️ New/Improved Technologies:

Recovery from industrial wastewater (especially from detergent, dye, and paper industries)

Membrane filtration and ion-exchange methods for purifying byproduct sodium sulfate.

🧠 Tech Shift Highlights:

Shift from synthetic production to waste stream recovery (circular economy).

Integration with zero-liquid discharge (ZLD) systems in large chemical plants.

👥 Users/Applications:

Detergent manufacturing

Paper pulping (Kraft process)

Textile dyeing

Glass production

🔮 Overall Trends in 2025:

Sustainability Focus: Companies are switching to bio-based feedstocks, waste stream valorization, and renewable-powered processes.

Digitalization: Use of AI/IoT in process control for better energy and yield efficiency.

Circular Economy Integration: Recovering sodium salts from effluents or industrial waste is a major theme.

Keywords

major theme

industrial waste

synthetic production

ionexchange methods

detergent dye

industrial wastewater

sodium chloride

hcl production

buffering agent

optimize crystallization

green electricity

sodium carbonate

process control

precise control

energyintensive drying

acetic acid

nitric acid

lignocellulosic biomass automation

utilize acetic acid

produce nitric acid

realtime purity control

drying phases adoption

renewablepowered processes digitalization

dyeing food industry

molten salt systems

solar thermal integration

sustainably reducing dependency