Israel-Iran Conflict: June 2025 Overview

Background: Tensions escalated in early 2025 due to Israel’s continued targeting of Iranian nuclear and military assets.

Nature of Conflict: Not a full-scale war but characterized by:

Missile strikes and retaliations.

Cyber warfare.

Disruptions in shipping through the Persian Gulf and the Strait of Hormuz—vital for global energy and chemical shipments.

🇮🇳 India's Chemical Industry: Exposure & Impact

India is heavily dependent on the Middle East for:

Feedstock chemicals

Fertilizers

Oil-linked intermediates

The ongoing conflict has triggered supply shocks, price surges, and logistical challenges. Let's break this down by product categories and business scenarios.

🧪 1. Fertilizers & Agrochemicals

Key Products:

Urea, Ammonium Sulphate, DAP, Potassium Nitrate

Impact:

Iran is a key supplier of Urea and Ammonium compounds to India.

Ongoing conflict has:

Delayed shipments from Bandar Abbas port.

Increased insurance and freight costs for imports.

Pushed up domestic prices (Ammonium Sulphate +10–12%, Urea +8%).

Consequences:

Indian farmers may face higher input costs during kharif season.

Indian producers like RCF, GSFC, and NFL are under pressure to stabilize supply.

🏭 2. Basic & Commodity Chemicals

Key Products:

Methanol

Acetic Acid

Caustic Soda

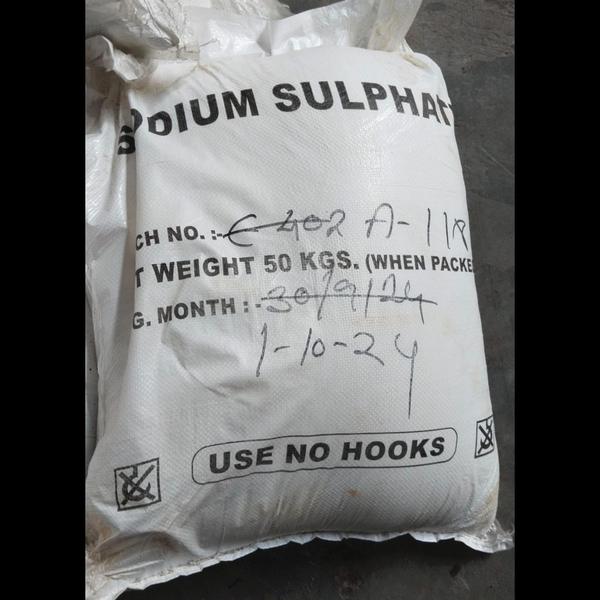

Sodium Nitrate / Sulphate / Acetate

Toluene & Benzene-based derivatives

Impact:

Feedstock methanol and acetic acid prices surged due to Gulf route risk.

Sodium-based chemicals, which depend on global soda ash and sulfur cycles, are now costlier due to energy price hikes.

Indian chemical processors are passing costs downstream, squeezing margins.

Example:

Sodium Acetate price jumped ~6% in Gujarat due to acetic acid import volatility.

⚗️ 3. Specialty & Fine Chemicals

Key Products:

Pharma intermediates

Agro-intermediates

Dyes and pigments

Impact:

These rely on petrochemical derivatives, now affected by:

Crude price fluctuations (Brent: $100/barrel average in May–June).

Volatile supply of precursors from Iran, UAE, and Saudi Arabia.

Effects:

Export-focused clusters in Ankleshwar, Vapi, and Panoli are facing:

Costlier imports

Delayed shipments

Pressure to find alternate suppliers

⚠️ 4. Logistics & Banking Channels

Instability in the Persian Gulf affects:

Indian imports via Iran and UAE routes

High container costs and delayed customs clearance

Banking channels with Iran (like UCO Bank) face tightening due to renewed U.S. and EU sanctions.

L/C issuance halted in many cases.

Indirect trade (via Oman/UAE) adds 10–15% in cost.

📊 Broader Industry Effects in India

Area Description

Production Cost Rising across all chemical verticals due to energy, shipping, and input volatility

Import Dependency Rising risk for products sourced from Iran/Gulf (urea, methanol, ammonia)

Domestic Manufacturers Slight advantage as buyers shift from risky imports to local supply

Export Potential Indian exporters gain some edge in Europe/SE Asia, filling Iran's gap

Government Response Exploring alternate routes (Russia, Turkmenistan), increased subsidies

🌍 Strategic Shifts & Business Advice

✅ Opportunities:

Local chemical players should capitalize on the shift toward 'China +1 + India' sourcing in the global market.

Focus on high-demand exports: sodium-based salts, acid dyes, and agro intermediates.

🚫 Risks:

Continued conflict may lead to shipping embargoes, currency volatility, or even cyberattacks on supply chains.

Iran-linked supply contracts are increasingly seen as high-risk.

🧭 Recommendations:

Diversify sourcing: Look to Egypt, Oman, or even Eastern Europe for sensitive imports.

Stock critical intermediates: Especially for monsoon season when demand rises.

Digitize trade tracking: Use ERP/CRM tools to monitor supplier risk and logistic delays.

Tap into government incentive schemes: Especially under PLI for Chemicals and Agri Inputs.

🔚 Conclusion

The Israel-Iran tension is a geopolitical flashpoint with real, material effects on India’s chemical trade. It has led to:

Costlier imports

Logistics disruptions

Greater demand for domestic output

While this is a challenge, it is also a chance for Indian chemical manufacturers and traders to reposition themselves as reliable global players.

Keywords

iran uae

buyers shift

energy shipping

domestic output

geopolitical flashpoint

israeliran tension

erpcrm tools

monsoon season

eastern europe

egypt oman

risky imports

products sourced

omanuae adds 1015

ankleshwar vapi

petrochemical derivatives

pigments impact

sulfur cycles

rcf gsfc

imports pushed

freight costs

delayed shipments

ammonium compounds

product categories

middle east

heavily dependent

persian gulf

missile strikes

fullscale war

iranian nuclear

gujarat due

costlier due

early 2025 due

key supplier

ongoing conflict

global energy

india ongoing conflict

chemical verticals due

monitor supplier risk

reliable global players

global market focus

global soda ash

indian chemical manufacturers

indias chemical trade

real material effects

agri inputs conclusion

government incentive schemes

logistic delays tap

cases indirect trade

mayjune volatile supply

military assets nature

israels continued targeting