how to manufacture (factory process of) sodium sulphate...

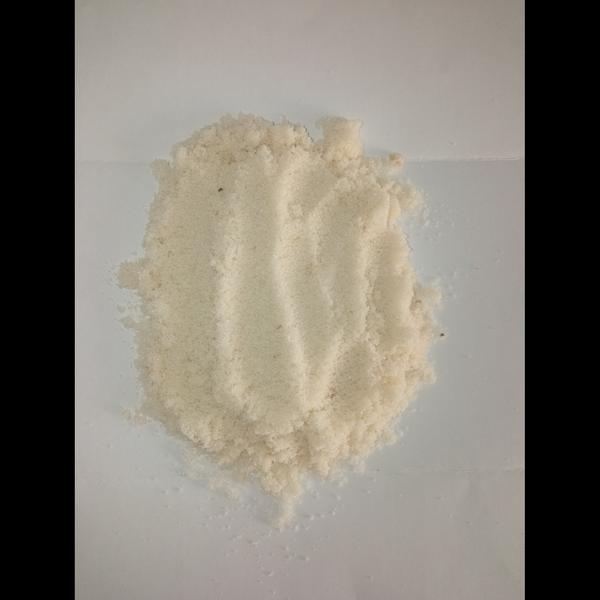

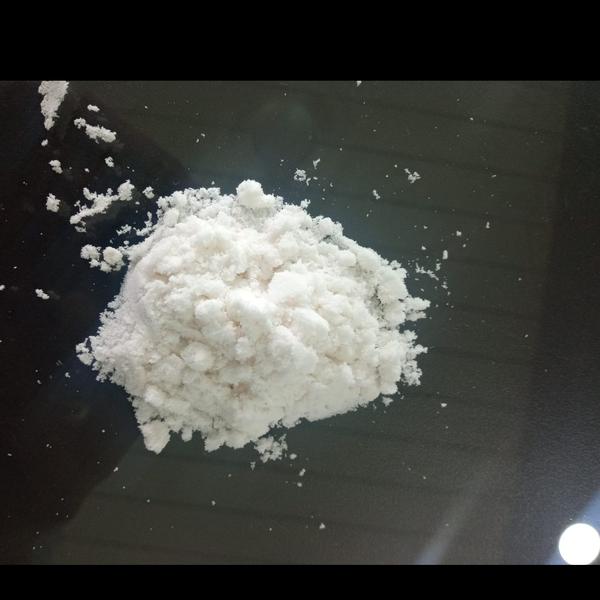

anufacturing Process of Sodium Sulphate (Na₂SO₄)

Sodium sulphate can be produced by several methods — depending on available raw materials and industrial scale. The main commercial routes are:

From Sodium Chloride and Sulfuric Acid (Mannheim Process)

Chemical Reaction:

Process Steps:

Sodium chloride (common salt) is reacted with concentrated sulfuric acid.

The reaction is done in a Mannheim furnace at 600–700°C.

Hydrogen chloride gas (HCl) is evolved and collected.

Solid sodium sulphate remains in the furnace and is removed, cooled, and purified.

Products:

Sodium sulphate (main product)

Hydrochloric acid gas (by-product)

Advantages: Simple and continuous process.

Disadvantages: High temperature required, corrosive gases.

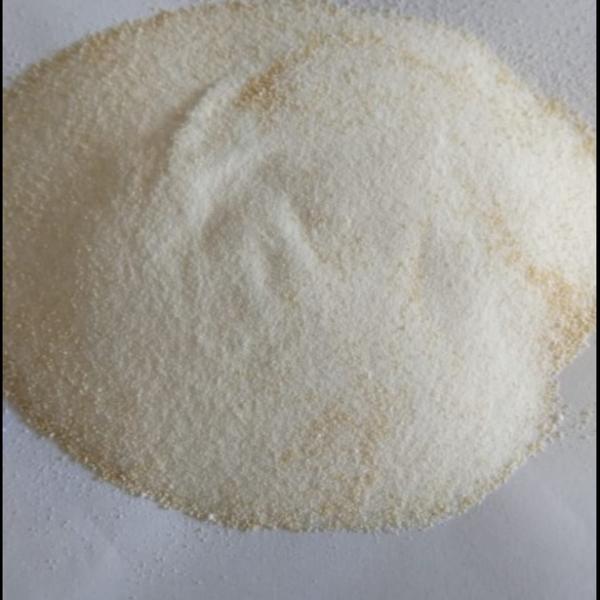

2.From Glauber’s Salt (Decahydrate Form)

Sodium sulphate naturally occurs as Glauber’s salt (Na₂SO₄·10H₂O).

• Sodium Sulphate for Glass Manufacturing

• Sodium Sulphate for Kraft Process

• Sodium Sulphate for Paper Industry

• Industrial Chemicals for Glass Production

• • Request Sodium Sulphate Quote

• • Bulk Sodium Sulphate Pricing

• • Sodium Sulphate MSDS Download

• • REACH-Compliant Sodium Sulphate

• • Sodium Sulphate with COA and SGS Certification

• • “Get a Free Quote Now”

• • “Download Product Specifications”

Process:

Mining or extraction of Glauber’s salt.

Heating (calcination) removes water of crystallization

The anhydrous salt is dried and packed.

Used where natural deposits exist.

Raw Materials Required

Sodium chloride (common salt)

Sulfuric acid (H₂SO₄)

Fuel for furnace (gas/coal)

Water and cooling system

Applications

Detergent manufacturing

Glass industry

Kraft pulp process (paper)

Textile dyeing and finishing

As filler in powder detergents

As thermal storage (in decahydrate form)