What is made

Sodium acetate (anhydrous) — NaC₂H₃O₂ (molar mass ≈ 82.0338 g·mol⁻¹). Typical forms: anhydrous and trihydrate (common lab form).

Two simple chemical routes (balanced)

From sodium hydroxide (neutralization)

CH₃COOH + NaOH → CH₃COONa + H₂O

From sodium bicarbonate (gentler, gas evolution)

CH₃COOH + NaHCO₃ → CH₃COONa + CO₂↑ + H₂O

Both give sodium acetate; choose NaOH for a water-salt-free approach (but exothermic), or NaHCO₃ if you want a milder reaction (CO₂ evolved — useful in lab demos).

Lab-scale example calculations (careful stoichiometry)

Molar masses used (rounded):

NaC₂H₃O₂ = 82.0338 g·mol⁻¹

CH₃COOH = 60.0520 g·mol⁻¹

NaOH = 39.9971 g·mol⁻¹

NaHCO₃ = 84.0066 g·mol⁻¹

Target: prepare 100.0 g anhydrous sodium acetate

Required moles = 100.0 ÷ 82.0338 = 1.2190 mol

If using NaOH:

CH₃COOH needed = 1.2190 × 60.0520 = 73.20 g

NaOH needed = 1.2190 × 39.9971 = 48.76 g

If using NaHCO₃:

CH₃COOH needed = 73.20 g (same)

NaHCO₃ needed = 1.2190 × 84.0066 = 102.40 g

(You may instead measure by volume when using glacial acetic acid — convert by density: glacial acetic acid ≈ 1.049 g·mL⁻¹.)

For a 1.000 mol batch (useful reference):

Sodium acetate yield = 82.0338 g

React with 60.0520 g acetic acid and 39.9971 g NaOH (or 84.0066 g NaHCO₃).

Practical lab procedure (small batch using NaHCO₃ — recommended for safety)

Materials: glacial acetic acid (or 10%–20% v/v solution), sodium bicarbonate, distilled water, ice bath, stirrer, filter paper, oven or vacuum oven.

Dissolve the calculated mass of NaHCO₃ in ~2–4× the final mass of distilled water (to form a clear suspension).

Place the bicarbonate solution in an ice bath and begin stirring.

Slowly add the measured acetic acid to the bicarbonate solution dropwise — CO₂ will evolve. Add with good stirring and keep temperature controlled (CO₂ evolution is mildly exothermic).

After addition, stir 10–20 min to ensure reaction completes. You should have a clear solution once CO₂ evolution subsides.

Filter if there are insolubles.

Concentrate the solution under reduced pressure or by gentle heating to induce crystallization (cool to 0–5 °C to maximize yield of trihydrate/anhydrate depending on temperature).

Collect crystals by filtration or centrifuge.

Sodium Acetate

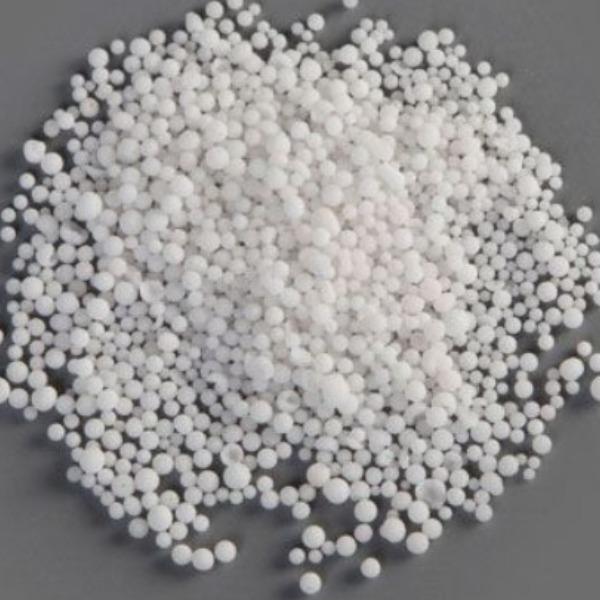

Sodium Acetate Anhydrous

Sodium Acetate Trihydrate

NaC₂H₃O₂

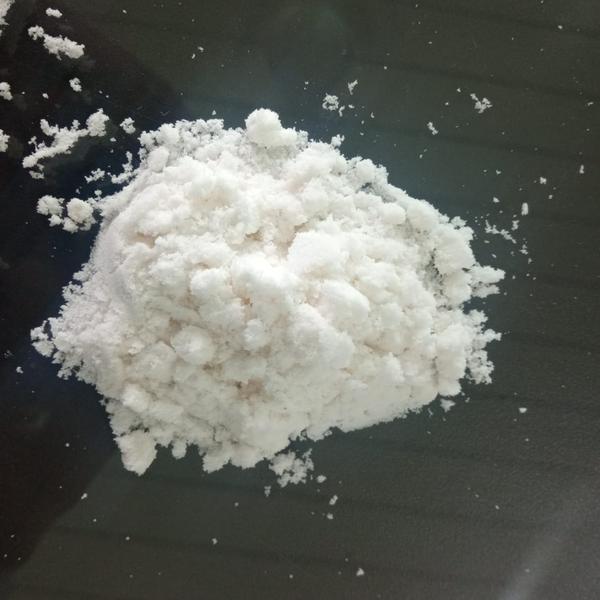

Sodium Acetate Powder

High Purity Sodium Acetate

Industrial Sodium Acetate

Dry crystals:

For trihydrate: store as-is (many labs use trihydrate).

For anhydrous: dry in an oven or vacuum oven at 110–120 °C (or per validated drying profile) until constant weight. Use vacuum drying if possible to prevent decomposition.

Mill/sieve to required particle size and pack.

Notes: If using NaOH instead, add NaOH solution into acetic acid (or add acetic acid to NaOH slowly) with cooling. Adding base into acid causes a vigorous exotherm if done too fast — control addition rate and temperature.

Industrial / plant-scale overview

Neutralization reactor (jacketed) — control pH to ~7.0 (1:1 mole basis). Add base slowly with cooling and pH monitoring.

Clarification / filtration — remove insoluble impurities.

Evaporation/crystallization — controlled evaporation and seeded crystallization to target crystal form (anhydrous vs trihydrate).

Centrifuge / filter press — separate crystals.

Drying — tray or fluid-bed drier or vacuum drier to required residual moisture.

Milling & sieving — particle size control.

Packaging — bagging or bulk. QA sampling for each lot.

Typical product specifications (example template — replace values with lab data)

Product: Sodium acetate (NaC₂H₃O₂) — anhydrous / trihydrate (specify)

Assay (as NaC₂H₃O₂): ≥ 99.0 % (example)

Appearance: White crystalline powder

Moisture (if anhydrous): ≤ 0.5 % w/w

pH (1% solution): ~8.0–9.0 (depends on form)

Chloride (Cl⁻): ≤ 0.01 %

Sulfate (SO₄²⁻): ≤ 0.01 %

Iron (Fe): ≤ 5 ppm

Residue on ignition / carbonate: ≤ specified limit

Typical particle size: 100% < 2 mm (customizable)

Packaging: 25 kg / 50 kg kraft bags, jumbo bag, bulk

(Validate each parameter with lab analysis and list detection methods on COA.)

Quality control & tests

Assay by titration or ion chromatography.

Moisture by Karl Fischer or loss on drying.

Impurities by ICP (metals), ion chromatography (halides, sulfate).

pH of 1% aqueous solution.

Crystallinity/water of hydration by TGA / DSC.

Safety, handling & storage

Acetic acid (glacial) is corrosive; use gloves, goggles, fume hood.

NaOH is caustic — handle with care (if used). Add slowly to avoid exotherm.

CO₂ evolution with bicarbonate route — provide ventilation.

SDS & COA: always supply to customers (you already use these CTAs).

Storage: keep dry in sealed containers. Hygroscopic under humid conditions (trihydrate forms). Avoid contamination.

Typical uses (so you can place on product page)

Buffering agent (laboratory & biochemical)

Textile and dyeing auxiliaries

Concrete admixtures / accelerators (in some formulations)

Food industry (as sodium acetate trihydrate: preservative E262) — note: food-grade production requires GMP and appropriate purity/certification

Hand warmers / heating pads (heat released during crystallization of supersaturated solution)

Corrosion inhibitor in certain packaging environments

Troubleshooting & tips

If product contains excess sodium carbonate — reduce exposure to CO₂ or neutralize more precisely.

Buy Sodium Acetate

Sodium Acetate supplier

Sodium Acetate manufacturer

Sodium Acetate bulk

Sodium Acetate sample batch

To get anhydrous without decomposition, use controlled vacuum drying and avoid temperatures above decomposition point.

Seed crystallization to control crystal habit and size.

If you want, I can now:

Draft a step-by-step SOP formatted for your plant or lab (with equipment list and hazard controls),

Create a one‑page product datasheet (PDF) with the specs above, or

Provide exact procedural volumes using your preferred batch size (tell me target mass or skip — I can use example sizes).

Which one should I generate next?

Sodium Acetate crystallization

Sodium Acetate manufacturing

Sodium Acetate production process

Sodium Acetate solution

Sodium Acetate storage & handling

Sodium Acetate anhydrous drying

Sodium Acetate trihydrate preparation

Sodium Acetate quality control

Safety / Compliance Keywords

SDS Sodium Acetate

COA Sodium Acetate

Sodium Acetate MSDS

Sodium Acetate safe handling

Sodium Acetate chemical supplier

Purchase / Marketing Keywords

Buy Sodium Acetate

Sodium Acetate supplier

Sodium Acetate manufacturer

Sodium Acetate bulk

Sodium Acetate sample batch

If you want, I can create a ready-to-use list of 50+ long-tail SEO phrases combining product, application, and purchase intent keywords specifically for your Laxmi Enterprise website and catalog — these can help rank on Google for chemical buyers.

Do you want me to do that next?

Keywords

Sodium acetate safety handling precautions

Sodium acetate food grade specifications

Sodium acetate buffer applications

Sodium acetate quality control tests

Sodium acetate anhydrous drying methods

Sodium acetate storage and handling

Sodium acetate crystallization process

Industrial sodium acetate production

How to prepare sodium acetate

Sodium acetate manufacturing process