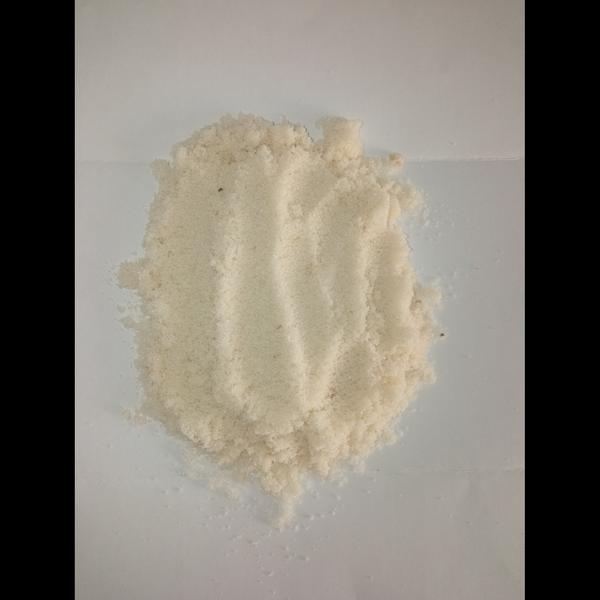

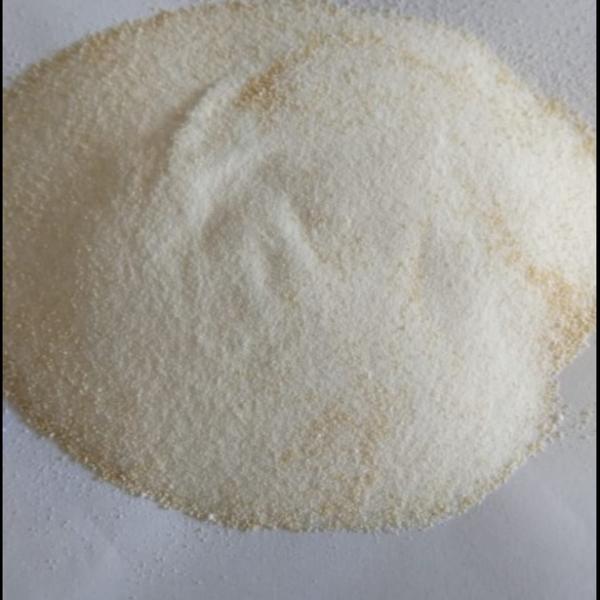

CATALYTIC USES OF SODIUM NITRATE (NaNO₃)

Manufactured by Laxmi Enterprise, Vadodara, Gujarat

🔹 1. Introduction

Sodium Nitrate (NaNO₃) is a powerful oxidizing agent that can act as a catalyst or catalytic promoter in several chemical and metallurgical reactions.

Its catalytic role is mainly due to its ability to:

Supply oxygen atoms during high-temperature reactions

Facilitate redox reactions

Stabilize reaction intermediates

Enhance reaction kinetics and thermal efficiency

The high-purity Sodium Nitrate from Laxmi Enterprise, Vadodara ensures consistent catalytic performance with minimal impurities, making it suitable for both laboratory and industrial-scale applications.

🔬 2. Mechanism of Catalytic Action

At elevated temperatures (above 300°C), Sodium Nitrate can decompose partially into Sodium Nitrite (NaNO₂) and oxygen

Curing Salt Additive

Food-Grade Nitrate Preservative

Meat Curing Ingredients

Preservatives for Processed Meat

Sodium Nitrate for Explosives

Oxidizer Chemicals Supplier

Pyrotechnic Grade Sodium Nitrate

Blasting Compound Ingredients

Mining Chemicals Supplier

The released oxygen acts as a reactive oxidizing species, which helps in:

Catalyzing oxidation reactions

Reducing carbon deposits or organic residues

Enhancing conversion efficiency in metal and chemical processes

Thus, NaNO₃ acts as a solid oxygen donor catalyst — promoting clean, complete, and accelerated reactions.

Industrial Users and Applications

Industry Catalytic Role of Sodium Nitrate

Chemical & Pharmaceutical Oxidation catalyst in synthesis reactions

Metallurgical / Heat Treatment Molten salt bath oxidizer and surface finisher

Dye & Pigment Industry Catalytic oxidizer in aromatic nitration

Glass & Ceramic Plants Clarifying and melting aid catalyst

Explosive & Pyrotechnic Oxygen supplier in combustion formulations

Environmental Systems Oxidation catalyst for waste treatment

Major Catalytic Applications of Sodium Nitrate

(A) Organic Chemical Synthesis

Used as an oxidizing catalyst in the manufacture of:

Nitro compounds

Dyes and intermediates

Aromatic nitration reactions

Helps in converting alcohols → aldehydes → acids via oxidation.

Improves yield and reduces side products.

Metal Heat Treatment & Surface Oxidation

Sodium Nitrate acts as a catalytic oxidizer in nitrate-nitrite salt baths used for:

Metal cleaning

Surface oxidation (bluing)

Tempering and annealing

In molten salt baths, NaNO₃ promotes uniform oxidation and scaling control, producing clean, corrosion-resistant metal surfaces.

Typical Bath Composition:

50% NaNO₃ + 50% NaNO₂ (by weight)

Operates at 450–550°C for carbon steel and alloy treatment.

Combustion and Pyrotechnics

Acts as a combustion catalyst in solid propellants, fireworks, and explosives.

The oxygen released from NaNO₃ ensures complete combustion and higher burning rate stability.

Used in formulations to regulate reaction temperature and minimize smoke emission.

Catalytic Support in Glass & Ceramics

In glass manufacturing, sodium nitrate acts as a melting and oxidizing catalyst to remove carbonaceous impurities.

Improves clarity, brightness, and homogeneity of molten glass.

Functions synergistically with other fluxes like sodium carbonate and silica.

Catalyst Regeneration

In refining and chemical industries, sodium nitrate is used to regenerate spent catalysts, particularly in:

Vanadium-based catalysts for sulfuric acid production

Copper or nickel catalysts for hydrogenation/dehydrogenation

NaNO₃ oxidizes metallic residues and restores catalyst activity.

Waste Treatment & Pollution Control

Used as a catalytic oxidizer in wastewater and flue gas treatment systems.

Converts cyanides, sulfides, and organic pollutants into less harmful oxidized forms.

Ensures cleaner discharge and faster degradation of industrial effluents.

SODIUM NITRATE (NaNO₃)

Manufactured by Laxmi Enterprise, Vadodara, Gujarat