Sodium Sulphate Decahydrate (Na₂SO₄·10H₂O) — also called Glauber’s Salt — is used for thermal energy storage (TES) and how the process works scientifically and industrially.

🔷 1. Introduction: What is Sodium Sulphate Decahydrate (Glauber’s Salt)?

Chemical formula: Na₂SO₄·10H₂O

Common name: Glauber’s Salt

Molecular weight: 322 g/mol

Melting point: ~32–33°C

Latent heat of fusion: ≈ 254 kJ/kg

This high heat of fusion makes it excellent for storing and releasing thermal energy — particularly in phase change material (PCM) systems for low-temperature thermal energy storage.

🔷 2. Concept: How Thermal Energy Storage (TES) Works

In TES systems using phase change materials (PCMs), the material absorbs heat when melting and releases heat when solidifying — without a large change in temperature.

Example:

When Glauber’s salt melts (solid → liquid) at 32°C:

Na₂SO₄

cdotp

10H₂O (solid)

→

heat absorbed

Na₂SO₄ (aqueous)

+

10

𝐻

2

𝑂

Na₂SO₄cdotp10H₂O (solid)

heat absorbed

Na₂SO₄ (aqueous)+10H

2

O

This process stores energy as latent heat.

When the system cools:

Na₂SO₄ (aqueous)

+

10

𝐻

2

𝑂

→

heat released

Na₂SO₄

cdotp

10H₂O (solid)

Na₂SO₄ (aqueous)+10H

2

O

heat released

Na₂SO₄cdotp10H₂O (solid)

The salt crystallizes, releasing stored heat at almost constant temperature (~32°C).

🔷 3. Step-by-Step Working Process

Step 1: Charging (Heat Storage)

When the ambient or supplied temperature rises above 32°C, Glauber’s salt melts.

During melting, it absorbs heat energy from the environment (e.g., solar collectors or hot air).

The material becomes a liquid solution — storing energy as latent heat of fusion.

Step 2: Storage Phase

The molten Glauber’s salt is stored in insulated containers (often in steel or HDPE tanks).

It stays stable for several hours to days, maintaining its temperature near the melting point.

Step 3: Discharging (Heat Release)

When the temperature drops below 32°C, the solution starts crystallizing back to solid decahydrate.

The latent heat is released in this phase, providing warmth to the surroundings.

This energy can be used for:

Space heating

Drying operations

Greenhouse heating

Domestic hot water preheating

🔷 4. System Design Example (Simplified)

Component Purpose

PCM tank (Glauber’s salt) Stores the heat

Heat exchanger tubes Transfers heat in/out

Solar collector / Electric heater Provides input heat

Insulation layer Minimizes losses

Water or air circulation Transfers useful heat to application

🔷 5. Advantages of Glauber’s Salt as PCM

✅ High latent heat capacity → stores large amounts of energy per unit mass.

✅ Stable phase change temperature (32°C) → ideal for comfort heating.

✅ Inexpensive & non-toxic → readily available and environmentally safe.

✅ Good thermal conductivity compared to organic PCMs like paraffin.

🔷 6. Challenges & Modifications

Despite its benefits, raw Glauber’s salt has some issues:

Issue Explanation Solution

Phase separation Water separates after multiple cycles Add thickening agents (e.g., sodium carboxymethyl cellulose, bentonite)

Supercooling Crystallization delayed Add nucleating agents (e.g., borax, Na₂B₄O₇·10H₂O)

Volume change Expansion during melting Design flexible storage containers

By adding stabilizers, Glauber’s salt becomes reliable for hundreds of heat–cool cycles.

🔷 7. Industrial & Commercial Applications

Application Use of Sodium Sulphate Decahydrate

Solar water heating Stores heat during the day, releases at night

Building HVAC systems Thermal regulation for walls or ceilings

Refrigeration backup Maintains cold chain stability during power outages

Greenhouses Keeps temperature stable for crops

Thermal energy recovery systems Stores waste heat from industrial exhausts

🔷 8. Energy Example Calculation

For 1 kg of Glauber’s salt:

Latent heat = ~254 kJ/kg

So, 10 kg can store ≈ 2540 kJ (≈0.7 kWh) of thermal energy at 32°C.

That’s enough to maintain a small room’s temperature for several hours.

🔷 9. Summary of Benefits

Property Value Importance

Melting point 32–33°C Ideal for space heating

Latent heat 254 kJ/kg High storage density

Reusability 100s of cycles Long operational life

Cost Low Economical PCM

Safety Non-toxic Environment-friendly

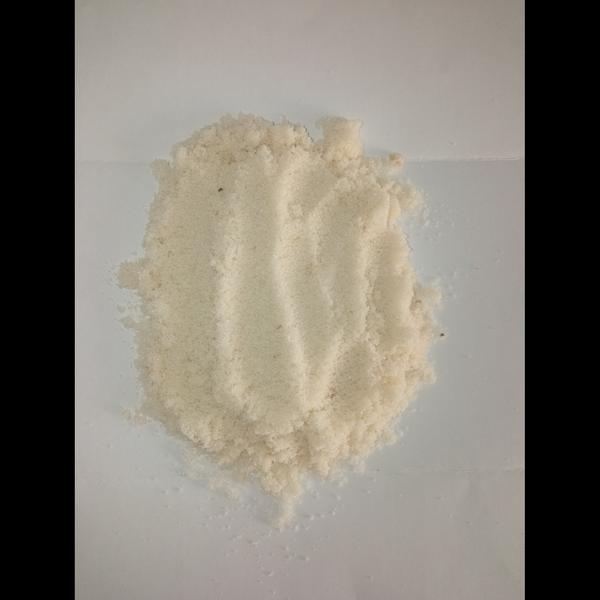

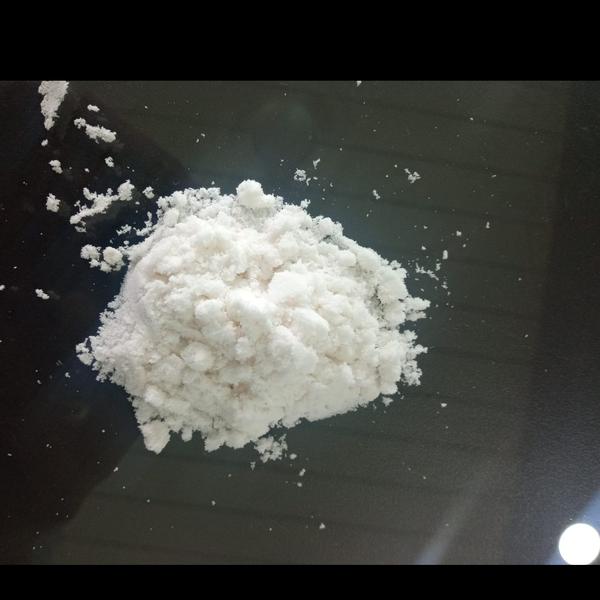

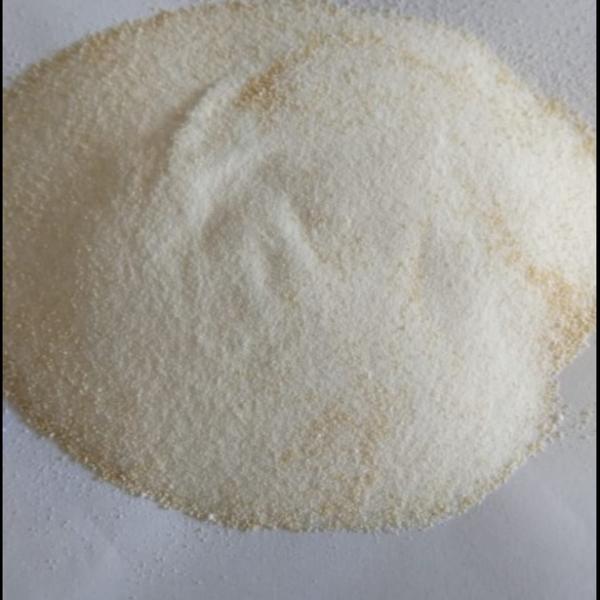

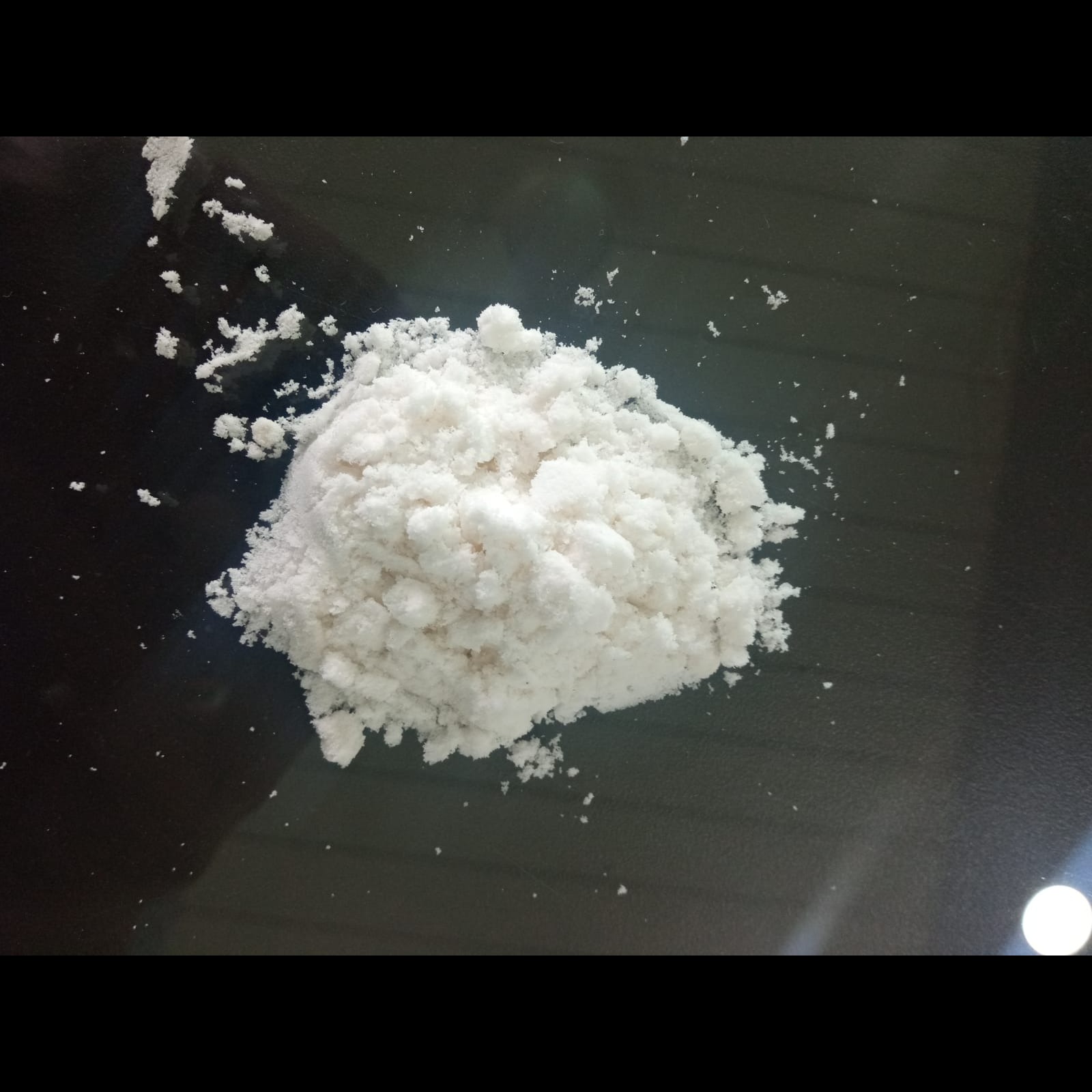

Sodium Sulhate in heat storage by Laxmi Enterprise, Vadodara, Gujarat, India.

• Sodium Sulphate for Sale

• Sodium Sulphate Supplier

• Sodium Sulphate Manufacturers

• Sodium Sulphate Exporter

• Sodium Sulphate Powder

• Industrial Grade Sodium Sulphate

• Anhydrous Sodium Sulphate

• Sodium Sulphate Bulk Supply

• Sodium Sulfate Distributor

Keywords

Sodium sulphate stability in thermal storage

Cost-effective PCM for heat storage

Sodium sulphate for space heating

Industrial sodium sulphate exporter Gujarat

Sodium Sulphate heat release process

Thermal energy storage system design

Sodium Sulphate heat storage applications

Phase change material for low-temperature thermal energy

Glauber’s Salt thermal energy storage

Sodium Sulphate Decahydrate heat storage